bonded thread factory

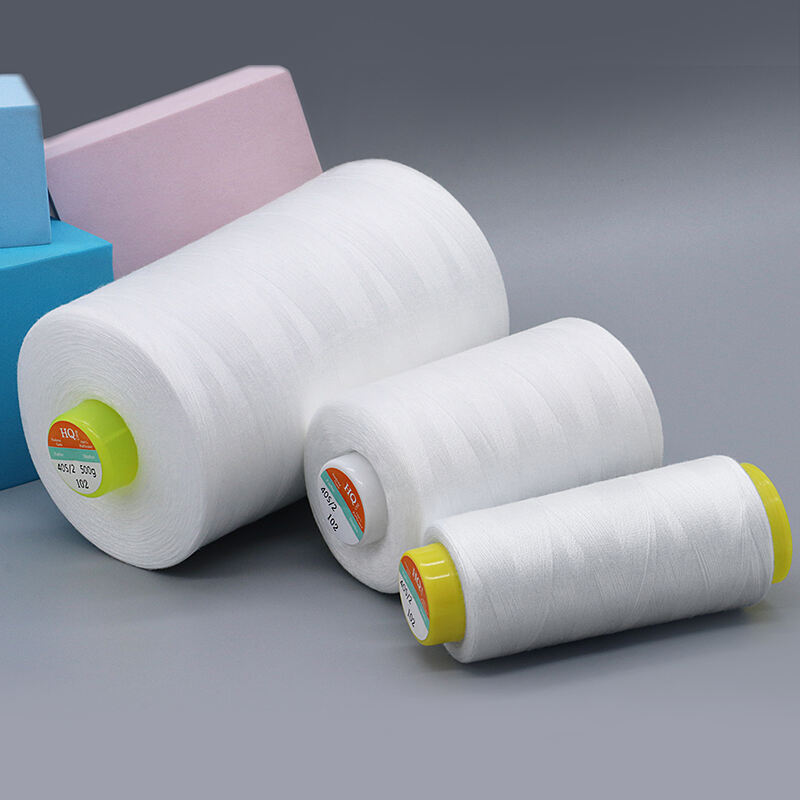

A bonded thread factory represents a cutting-edge manufacturing facility dedicated to producing high-quality bonded threads through innovative processing techniques. These specialized facilities employ advanced technologies to apply bonding agents to thread surfaces, creating superior strength and durability characteristics. The factory utilizes state-of-the-art equipment for precise control over the bonding process, ensuring consistent quality across all production batches. The manufacturing process involves multiple stages, including thread preparation, bonding agent application, curing, and quality control testing. Modern bonded thread factories incorporate automated systems for material handling, temperature control, and processing parameters to maintain optimal production conditions. These facilities are equipped with specialized testing laboratories to verify thread performance metrics, including tensile strength, abrasion resistance, and bonding effectiveness. The factory's production capabilities extend to various thread types, from industrial-grade heavy-duty threads to fine precision threads for specialized applications. Environmental control systems maintain ideal temperature and humidity levels throughout the facility, ensuring consistent bonding quality. The factory's workflow is designed for maximum efficiency, with dedicated areas for raw material storage, processing, quality control, and finished product packaging. Advanced inventory management systems track materials and products throughout the production cycle, ensuring timely delivery and maintaining product traceability.