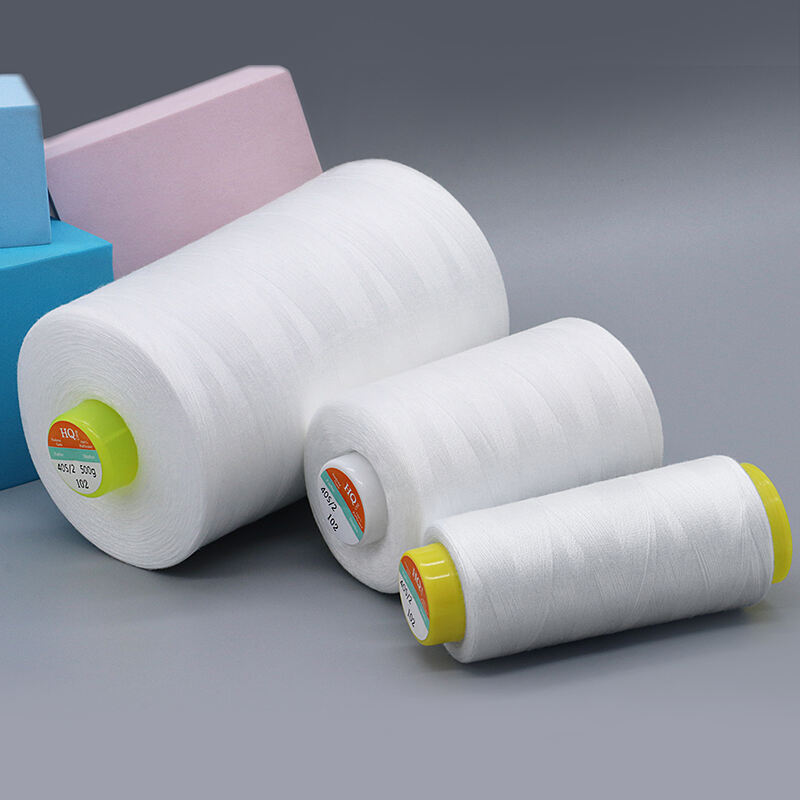

industrial sewing thread

Industrial sewing thread stands as a fundamental component in manufacturing, engineered specifically for heavy duty applications and continuous production environments. This specialized thread combines durability with precision engineering, featuring high tensile strength and consistent quality throughout its length. Made from various materials including polyester, nylon, and cotton, industrial sewing thread undergoes rigorous quality control processes to ensure optimal performance in automated sewing systems. The thread's construction incorporates advanced fiber technology that prevents fraying, reduces breakage, and maintains structural integrity under high speed sewing conditions. Its uniform thickness and smooth surface finish enable seamless feeding through industrial machines, while specialized coatings enhance lubricity and heat resistance. These threads are available in different weights, sizes, and finishes to accommodate diverse manufacturing needs, from automotive upholstery to heavy duty bags and technical textiles. The color fastness and chemical resistance of industrial sewing thread ensure lasting performance even in challenging environmental conditions, making it indispensable in professional manufacturing settings.